Air Control Balancing has the required personnel, expertise, and instrumentation to provide the following services:

Air Distribution & Hydronic Balancing

…of heating, ventilating and air conditioning systems during all phases of design and construction.

No matter how efficient and well-maintained a furnace or air conditioner, there’s still a chance it’s not providing even airflow through the building. That’s because the system relies on the building’s ductwork to distribute the air it warms or cools.

Problems with either the system itself or the ductwork can cause an air to be unevenly distributed or create negative air pressure in the building. This results in certain rooms never reaching a comfortable temperature, cold drafts, and areas that feel stuffy or humid compared to other parts of the building.

Air balancing is a method of testing your heating and cooling system to spot any problems that are causing uneven airflow or negative air pressure. Once identified, these problems can be corrected so every room gets the amount of air it needs. You stand to benefit in a number of ways.

Greater comfort — Balanced airflow means even temperatures throughout the whole building and fewer chilly drafts caused by outdoor air being drawn into the building. Building occupants won’t be forced to put on jackets and sweaters just to use parts of the building that are always chilly. In office buildings and schools, comfort promotes productivity.

Better indoor air quality — Low airflow allows indoor air contaminants, such as pollen and mold spores, to build up. It can also leave rooms feeling stale and stuffy. With balanced airflow, everyone in your building will enjoy healthier, fresher-smelling air.

Lower energy bills — When the temperature in one area never seems to be right, it’s tempting to crank up the heat or lower the A/C temperature for the whole building to compensate. Doing so only wastes energy. After correcting your building’s airflow, you’ll no longer need to do this. You can choose energy-efficient thermostat temperatures and still keep every room comfortable.

Sound and Vibration Testing

…of HVAC systems and equipment.

Sound and vibration affect all of us in our daily lives – from the smartphones we use, the cars we drive and the machines we operate, to the environment in which we all live. For many products, the legislation applies to maximum vibration or acoustic levels. Still, a well-balanced sound and vibration performance is also perceived as a sign of high quality, accuracy, comfort, sportiness or other important product characteristics by its users.

Noise and vibration testing is the process of measuring, analyzing or validating the dynamic characteristics of a system and its components, then creating and validating solutions to modify those characteristics to meet design objectives.

Noise and vibration testing helps to separate the dynamics related to operational sources from the structural dynamic properties and lets engineers identify root causes and targeted solutions to improve performance.

Indoor Air Quality Testing

…to verify ventilation effectiveness, proper outside air intake, and other aspects of IAQ.

While we are often concerned about the outdoor air quality near major cities or industrial areas, you should not overlook the quality of your air indoors. Indoor air quality is essential not only for your health but for your safety as well. To figure out your indoor air quality, you need to conduct an indoor air quality test.

Indoor air quality tests measure the air for things such as allergens, mold, and radon, among others. These tests can show whether the quality of your indoor air is either safe or dangerous. A good test will measure and tell you accurately what is in the air inside your home or office.

Building Systems Commissioning

…of HVAC systems and plumbing systems.

Commissioning is a process – a systematic process of ensuring that a building performs in accordance with the design intent, contract documents, and the owner’s operational needs. Commissioning is fundamental to the success of the whole-building design process.

When a building is initially commissioned it undergoes an intensive quality assurance process that begins during design and continues through construction, occupancy, and operations. Commissioning ensures that the new building operates initially as the owner intended and that building staff are prepared to operate and maintain its systems and equipment.

Cooling Tower Performances Testing

…to determine the tower’s capacity to perform as specified or designed.

We perform performance testing to evaluate your cooling towers’ capacity and efficiency. Performance tests with accurately calibrated instruments will demonstrate the thermal capability, cell balancing, and pumping conditions of your cooling tower. Diagnostic testing will pinpoint problems before they become critical.

Fume Hood Testing

…to ensure safe conditions in laboratory facilities and effective, economical fume hood performance.

A fume hood is a ventilated enclosure used to contain gases, vapors, and fumes. It is one of the most effective devices used to protect laboratory professionals from air contaminants and hazardous chemicals. Proper performance and use of the fume hood is essential in providing safety to the user and other laboratory personnel.

The standard fume hood certification includes face velocity testing to document and obtain an acceptable airflow and calculated total CFM volume, through the front opening of the hood with the sliding sash at a height that allows functional use.

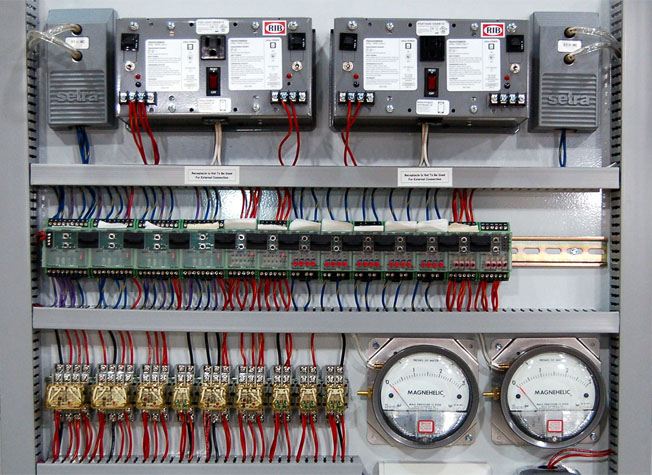

Verification of Control Systems

…to guarantee effective system operation.

The process of checking whether the design and performance of the instrumentation and control systems conform to the design standards and best practices.

Duct-Leakage Testing

…to ensure energy conservation and control of air movement, humidity and temperature.

A duct leakage tester is a diagnostic tool designed to measure the airtightness of forced air heating, ventilating and air-conditioning (HVAC) ductwork. A duct leakage tester consists of a calibrated fan for measuring an air flow rate and a pressure sensing device to measure the pressure created by the fan flow. The combination of pressure and fan flow measurements are used to determine the ductwork airtightness. The airtightness of ductwork is useful knowledge when trying to improve energy conservation.